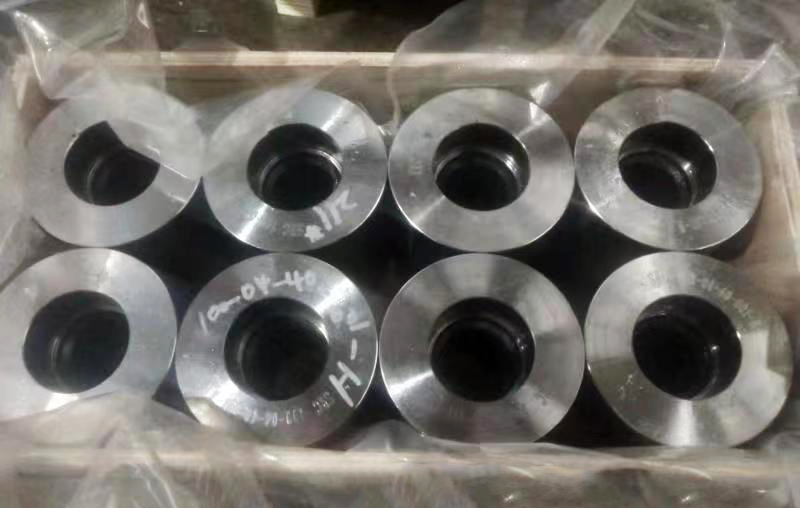

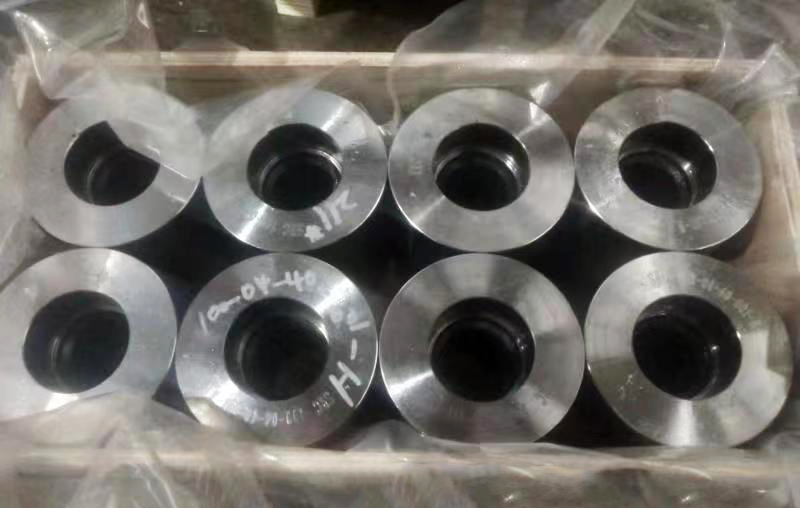

For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable part of wires export in the wires rolling process, it must be accorded with the requirements of high rigidity, good wear resistance (the service life is matched with the high-quality bearing), good thermal conductivity, a certain of red hardness, especially the high speed wires rolling (rolling speed is among 80-120m/s).

SRC guide rollers are available in a wide range of shapes, sizes and materials for a variety of applications such as conveyor lines and material handling.

The guide rollers currently available fall into three main categories:

(1)carbide tungsten guide roller

Carbide tungsten guide roller is made by tungsten carbide which could improve the mechanical characteristics of the cold rolled wire. They are used for removing any bends, irregularities, and mills left in the material that is being processed. Also could be used for wire straightening it could ensures that the final wire or rod will be consistent and free off defects.

(2)carbide titanium guide roller

Product features:

1、 Extremely low coefficient of friction and self-lubricating properties, so the guide roller working part of the wear is less, the output can be greatly improved

2、 The coefficient of thermal expansion is close to that of bearing steel. Bearings do not seize when heat hardened. The coefficient of thermal expansion of titanium carbide and tungsten carbide carbide is very different from that of steel.

3、Microstructure of titanium carbide and high chromium tool steel, with good thermal fatigue resistance.

4、Oxidation resistance, less magnetic, non-stick steel. Easy to process, after quenching only a little fine grinding can be processed into finished products, low processing costs, so the price is also low. This is also one of the main reasons why titanium carbide guide rollers are better than tungsten carbide guide rollers.

5、 Good hardness, good wear resistance.

(3)Forged D2 guide roller

All of the above guide rollers are available in stock and we can ensure better availability and faster delivery. Choosing SRC will save you time and effort in product design.

For the rolling mill, guide rollers (also called ring rollers, guide wheel) is an indispensable part of wires export in the wires rolling process, it must be accorded with the requirements of high rigidity, good wear resistance (the service life is matched with the high-quality bearing), good thermal conductivity, a certain of red hardness, especially the high speed wires rolling (rolling speed is among 80-120m/s).

SRC guide rollers are available in a wide range of shapes, sizes and materials for a variety of applications such as conveyor lines and material handling.

The guide rollers currently available fall into three main categories:

(1)carbide tungsten guide roller

Carbide tungsten guide roller is made by tungsten carbide which could improve the mechanical characteristics of the cold rolled wire. They are used for removing any bends, irregularities, and mills left in the material that is being processed. Also could be used for wire straightening it could ensures that the final wire or rod will be consistent and free off defects.

(2)carbide titanium guide roller

Product features:

1、 Extremely low coefficient of friction and self-lubricating properties, so the guide roller working part of the wear is less, the output can be greatly improved

2、 The coefficient of thermal expansion is close to that of bearing steel. Bearings do not seize when heat hardened. The coefficient of thermal expansion of titanium carbide and tungsten carbide carbide is very different from that of steel.

3、Microstructure of titanium carbide and high chromium tool steel, with good thermal fatigue resistance.

4、Oxidation resistance, less magnetic, non-stick steel. Easy to process, after quenching only a little fine grinding can be processed into finished products, low processing costs, so the price is also low. This is also one of the main reasons why titanium carbide guide rollers are better than tungsten carbide guide rollers.

5、 Good hardness, good wear resistance.

(3)Forged D2 guide roller

All of the above guide rollers are available in stock and we can ensure better availability and faster delivery. Choosing SRC will save you time and effort in product design.